What maintenance work should be done on electric steam boilers?

2022-02-28 11:19:20

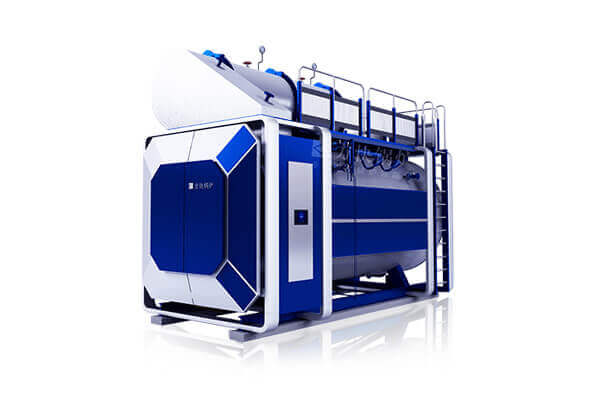

Electric steam boilers do not have a combustion chamber or chimney, and do not need to consider heat loss. The thermal efficiency can be maintained at about 98%, and a variety of advanced control systems are used, such as automatic sewage discharge, scale alarm and other functions. Various advantages make it trusted and used by more and more users.

However, you also cannot ignore the daily maintenance of electric steam boilers. Our Henan Fangkuai boiler manufacturer has summarized 12 maintenance items for your reference, hoping to help you better operate your own electric steam boilers.

1. Boiler water must be water that meets the standard after softening treatment.

2. When repairing and maintaining the boiler, the power supply must be cut off and the pressure must be relieved.

3. The boiler must be drained every day to ensure that the water in the boiler is clean.

4. Frequently check the operation status of key components such as power lines, water supply pumps, control boxes, pressure switches and safety valves, and find the cause and repair in time if there is an abnormality.

5. The water level gauge should be kept clean at all times, rinsed once a day to ensure the water level, and the safety valve should be moved once a day to prevent rust failure.

6. When the boiler stops running for a long time, the power supply should be cut off, and the water in the boiler and pipes should be drained to prevent freezing and rusting.

7. In the event of a sudden power failure, the power supply and the water inlet valve should be turned off in time.

8. Carry out the normal maintenance of the control box by "listening, smelling, seeing and touching". If abnormal phenomena are found, the power should be cut off immediately and repaired in time.

9. Regularly tighten the connecting screws on the electric heating pipe and the nuts on the flange.

10. The electric heating tube is easy to scale in the steam furnace. If there is no steam boiler with softened water equipment, it is recommended to disassemble the electric heating tube once a month to remove scale. If there is water treatment equipment, the electric heating tube should be disassembled to remove the scale once in about six months. When re-powering the heating tube, pay attention to the restoration of the connection, and fasten the screws on the flange. When tightening the screws, they should be tightened symmetrically and repeatedly to avoid water leakage.

11. When the boiler stops running, the power supply should be cut off, the control box should be opened, and the nuts of all electrical device connections should be checked, and the loose ones should be tightened to prevent bad contact from burning the wires and electrical devices.

12. The boiler must be cleaned and descaled once every six months or a year to ensure the efficiency and service life of the boiler.

However, you also cannot ignore the daily maintenance of electric steam boilers. Our Henan Fangkuai boiler manufacturer has summarized 12 maintenance items for your reference, hoping to help you better operate your own electric steam boilers.

1. Boiler water must be water that meets the standard after softening treatment.

2. When repairing and maintaining the boiler, the power supply must be cut off and the pressure must be relieved.

3. The boiler must be drained every day to ensure that the water in the boiler is clean.

4. Frequently check the operation status of key components such as power lines, water supply pumps, control boxes, pressure switches and safety valves, and find the cause and repair in time if there is an abnormality.

5. The water level gauge should be kept clean at all times, rinsed once a day to ensure the water level, and the safety valve should be moved once a day to prevent rust failure.

6. When the boiler stops running for a long time, the power supply should be cut off, and the water in the boiler and pipes should be drained to prevent freezing and rusting.

7. In the event of a sudden power failure, the power supply and the water inlet valve should be turned off in time.

8. Carry out the normal maintenance of the control box by "listening, smelling, seeing and touching". If abnormal phenomena are found, the power should be cut off immediately and repaired in time.

9. Regularly tighten the connecting screws on the electric heating pipe and the nuts on the flange.

10. The electric heating tube is easy to scale in the steam furnace. If there is no steam boiler with softened water equipment, it is recommended to disassemble the electric heating tube once a month to remove scale. If there is water treatment equipment, the electric heating tube should be disassembled to remove the scale once in about six months. When re-powering the heating tube, pay attention to the restoration of the connection, and fasten the screws on the flange. When tightening the screws, they should be tightened symmetrically and repeatedly to avoid water leakage.

11. When the boiler stops running, the power supply should be cut off, the control box should be opened, and the nuts of all electrical device connections should be checked, and the loose ones should be tightened to prevent bad contact from burning the wires and electrical devices.

12. The boiler must be cleaned and descaled once every six months or a year to ensure the efficiency and service life of the boiler.

Consultation

Consultation