4 ton gas boiler used in paper mill

2021-11-17 13:47:09

Gas boilers are used in a wide range of applications. Industrial production such as medical equipment disinfection, drug production, food processing, packaging production, etc. cannot do without it. The paper industry is also a large user of industrial gas boilers, and most of the boiler models used are 4 tons or Above 4 tons. Today we will talk about the 4-ton gas boiler type dedicated to paper mills.

1. Model of 4-ton gas boiler

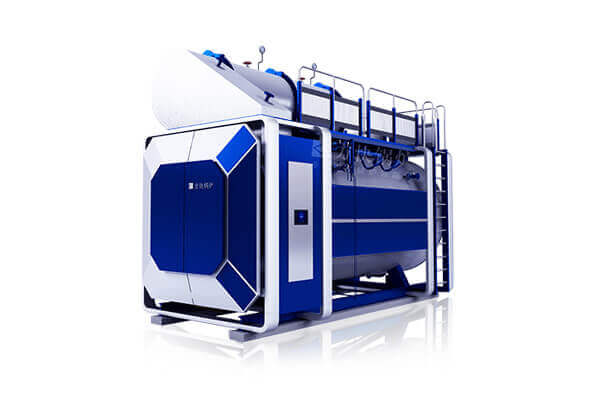

Combining our Fangkuai boiler's cooperation experience with 100+ paper mills, the gas-fired steam boiler model WNS4-1.25-Q is more suitable for the needs of paper mills.

The boiler consists of a condensing gas boiler body + energy saver + condenser + boiler auxiliary equipment; auxiliary equipment mainly includes: control cabinet, burner, make-up pump, condensing circulating water pump, energy saver, sub-cylinder, chimney, etc.

Advantages: The 4 ton gas boiler has sufficient output, high thermal efficiency, and low operating cost. In the paper production process, it can save users a lot of operating costs and increase profitability.

The coverage rate of the paper industry is very wide. When choosing a steam boiler, users need to choose the appropriate boiler selection based on the local environmental protection policy and actual operating cost analysis.

According to the different energy-saving effects, the 4-ton gas boiler can be divided into two types: horizontal three-pass gas boiler and condensing integrated gas boiler;

According to different environmental protection effects, it can be divided into three types: gas-fired boilers with a nitrogen oxide emission standard of 150-200mg, 80mg gas-fired boilers, and 30mg gas-fired boilers.

Among them, the price of general gas boilers is low, followed by 80mg, and 30mg is higher.

Therefore, in order to ensure a reasonable selection of boilers, users in the paper industry need to pay attention to:

1. The fuel selection must meet environmental protection requirements;

2. The flue gas emission meets the local environmental protection policy;

3. Choose boilers with good energy-saving effects to ensure profitability;

1. Model of 4-ton gas boiler

Combining our Fangkuai boiler's cooperation experience with 100+ paper mills, the gas-fired steam boiler model WNS4-1.25-Q is more suitable for the needs of paper mills.

The boiler consists of a condensing gas boiler body + energy saver + condenser + boiler auxiliary equipment; auxiliary equipment mainly includes: control cabinet, burner, make-up pump, condensing circulating water pump, energy saver, sub-cylinder, chimney, etc.

Advantages: The 4 ton gas boiler has sufficient output, high thermal efficiency, and low operating cost. In the paper production process, it can save users a lot of operating costs and increase profitability.

The coverage rate of the paper industry is very wide. When choosing a steam boiler, users need to choose the appropriate boiler selection based on the local environmental protection policy and actual operating cost analysis.

According to the different energy-saving effects, the 4-ton gas boiler can be divided into two types: horizontal three-pass gas boiler and condensing integrated gas boiler;

According to different environmental protection effects, it can be divided into three types: gas-fired boilers with a nitrogen oxide emission standard of 150-200mg, 80mg gas-fired boilers, and 30mg gas-fired boilers.

Among them, the price of general gas boilers is low, followed by 80mg, and 30mg is higher.

Therefore, in order to ensure a reasonable selection of boilers, users in the paper industry need to pay attention to:

1. The fuel selection must meet environmental protection requirements;

2. The flue gas emission meets the local environmental protection policy;

3. Choose boilers with good energy-saving effects to ensure profitability;

Consultation

Consultation