Two main factors causing corrosion of gas boilers

2022-02-14 14:28:08

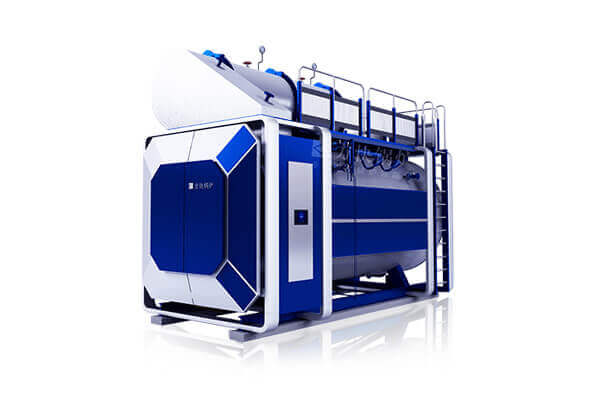

If the current gas boilers perform various operations strictly in accordance with the operating requirements, and carry out regular inspection and maintenance, the problems in the operation process will be greatly reduced, the service life can reach 15-20 years, and the cost performance will be higher. Corrosion is an important factor affecting the service life of the boiler. If the boiler is corroded due to operator error or failure to perform maintenance work on time, the thickness of the boiler body will become thinner, the thermal efficiency will be reduced, and the service life will be shortened.

There are two main reasons for the corrosion of gas boilers, namely flue gas corrosion and scale corrosion. This kind of corrosion is accumulated over time. If it is not paid attention to, it will cause damage to the equipment, and even serious accidents will occur. Today, let's talk about the reasons for the corrosion of gas boilers in detail, so that we can start from the reasons and prevent corrosion from happening again.

The primary cause of boiler corrosion is flue gas. The boiler needs fuel to burn, and the combustion process will inevitably produce flue gas. When the high-temperature flue gas passes through the boiler wall, condensation will occur, and the formed condensed water will seriously corrode the metal surface.

Another major cause of boiler corrosion is scale corrosion. For example, if the kettle we use to boil water is used for a long time, scale will appear inside the kettle, which will first affect the quality of drinking water, and secondly, it will take longer to boil a kettle of water. As a "monster" that is hundreds of thousands of times larger than a kettle, if it corrodes, it will be very harmful.

Therefore, it is recommended that all enterprises and units that use gas boilers must choose a standard and reliable manufacturer when purchasing gas boilers. The water used in the boiler must also be softened, so as to ensure the safe production of the boiler and make it more durable.

There are two main reasons for the corrosion of gas boilers, namely flue gas corrosion and scale corrosion. This kind of corrosion is accumulated over time. If it is not paid attention to, it will cause damage to the equipment, and even serious accidents will occur. Today, let's talk about the reasons for the corrosion of gas boilers in detail, so that we can start from the reasons and prevent corrosion from happening again.

The primary cause of boiler corrosion is flue gas. The boiler needs fuel to burn, and the combustion process will inevitably produce flue gas. When the high-temperature flue gas passes through the boiler wall, condensation will occur, and the formed condensed water will seriously corrode the metal surface.

Another major cause of boiler corrosion is scale corrosion. For example, if the kettle we use to boil water is used for a long time, scale will appear inside the kettle, which will first affect the quality of drinking water, and secondly, it will take longer to boil a kettle of water. As a "monster" that is hundreds of thousands of times larger than a kettle, if it corrodes, it will be very harmful.

Therefore, it is recommended that all enterprises and units that use gas boilers must choose a standard and reliable manufacturer when purchasing gas boilers. The water used in the boiler must also be softened, so as to ensure the safe production of the boiler and make it more durable.

Consultation

Consultation