gas steam boiler in textile industry

2022-04-14 16:19:57

Clothing with bright colors and rich designs can greatly improve our happiness in life. In the process of garment processing, a large amount of steam is required to complete various processes such as raw material processing, drying, pressing, painting and dyeing. This shows the importance of steam boilers. As a well-known steam boiler supplier, Fangkuai Boiler Manufacturer has joined forces with a large garment processing enterprise to provide equipment support for building a high-end garment enterprise in Asia.

The raw materials of many garments are some cotton and linen materials, and many processing techniques are required to turn them into garments. Because clothing production has high requirements for steam boilers, how to purchase boiler equipment with good performance, high degree of automation and high cost performance has become the primary problem for the company to solve.

As one of the leading brands in the domestic boiler industry, Fangkuai Boiler has rich experience in project cooperation with textile production enterprises. Taking into account the company's textile production, material drying, drying, printing and dyeing and other processes and equipment not only have strict requirements on steam purity, cleanliness, and whether continuous production can be maintained, but many equipment also have steam pressure, temperature, moisture content. Both are important.

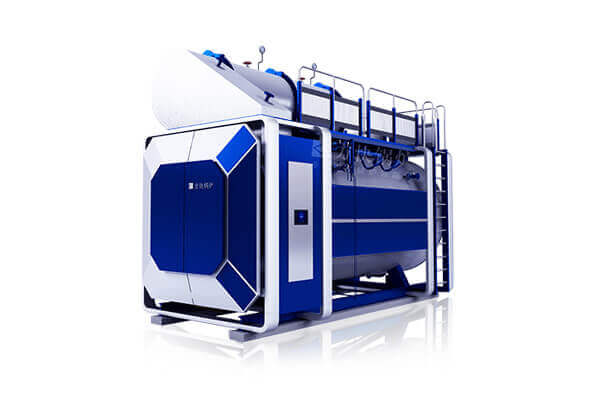

Based on the actual needs of customers, Fangkuai Boiler customized a WNS series gas-fired steam boiler (WNS8-1.25-Y.Q) with an output of 8 tons. This series of gas boilers have the advantages of sufficient output, high thermal efficiency and good environmental protection effect. The equipped automatic control system can accurately control the pressure, temperature and water level of the boiler to ensure the long-term stable operation of the boiler.

After the integration and analysis of various materials, the development model of Fangkuai boiler with equal emphasis on quality and service has emerged in the boiler industry, and finally won the recognition and favor of the textile enterprise. In the process of using the boiler, it also proves the equipment quality of Fangkuai boiler, which provides strong power support for the vigorous battle of the textile industry.

The raw materials of many garments are some cotton and linen materials, and many processing techniques are required to turn them into garments. Because clothing production has high requirements for steam boilers, how to purchase boiler equipment with good performance, high degree of automation and high cost performance has become the primary problem for the company to solve.

As one of the leading brands in the domestic boiler industry, Fangkuai Boiler has rich experience in project cooperation with textile production enterprises. Taking into account the company's textile production, material drying, drying, printing and dyeing and other processes and equipment not only have strict requirements on steam purity, cleanliness, and whether continuous production can be maintained, but many equipment also have steam pressure, temperature, moisture content. Both are important.

Based on the actual needs of customers, Fangkuai Boiler customized a WNS series gas-fired steam boiler (WNS8-1.25-Y.Q) with an output of 8 tons. This series of gas boilers have the advantages of sufficient output, high thermal efficiency and good environmental protection effect. The equipped automatic control system can accurately control the pressure, temperature and water level of the boiler to ensure the long-term stable operation of the boiler.

After the integration and analysis of various materials, the development model of Fangkuai boiler with equal emphasis on quality and service has emerged in the boiler industry, and finally won the recognition and favor of the textile enterprise. In the process of using the boiler, it also proves the equipment quality of Fangkuai boiler, which provides strong power support for the vigorous battle of the textile industry.

Consultation

Consultation