Steam boilers used in textile mills

2022-04-06 15:45:42

Textile enterprises mainly use steam boilers for the processing and processing of raw materials. The high-temperature steam output by the steam boilers is directly or indirectly transported to various processes of textile production.

Which type of steam boiler is more suitable for textile enterprises to choose? This depends not only on the actual needs of textile enterprises, but also on external environmental requirements, such as local environmental protection standards, water quality discharge standards, and so on.

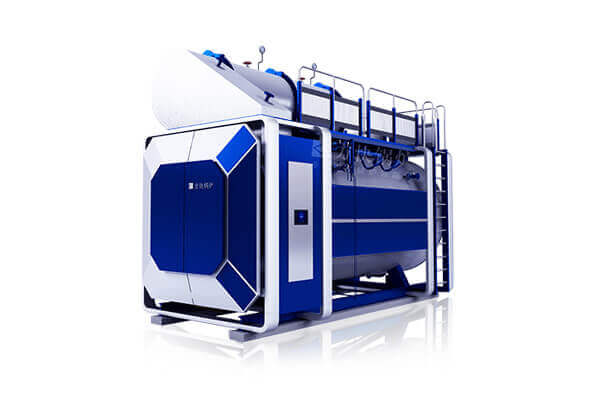

Which steam boiler is better for textile enterprises? Fangkuai boiler technicians recommend "Euromonitor" series customized gas steam boilers.

The "Euromonitor" series of customized gas-fired steam boilers use gas fuel, and the biggest feature is that the steam is very fast. After the boiler is started, it only needs to wait for 3-5 minutes to output high-temperature and high-quality steam with a temperature above 194°C. The steam has a very high purity and almost no water. This can save a fuel input cost for textile enterprises using steam boilers. Many other types of steam boilers require fuel to burn continuously for an hour or more to output high-temperature steam, and the fuel cost in this short period of time is wasted. This value will be higher if the boiler is started frequently.

The "Euromonitor" series of customized gas-fired steam boilers can also achieve low nitrogen emissions, and emissions below 18mg can be used in any city in my country. Beijing, Shanghai, Zhengzhou, Xi'an and other cities have implemented the 30mg emission standard, and 18mg can be used in that city, so you can avoid the strict inspection of the environmental protection department.

The "Euromonitor" series of customized gas-fired steam boilers are still very small in size and have very low requirements on the boiler room. It can be used in basement, semi-underground and above ground.

"Euromonitor" series of customized gas-fired steam boilers can also customize specific tonnage according to the needs of users, which is very flexible.

Which type of steam boiler is more suitable for textile enterprises to choose? This depends not only on the actual needs of textile enterprises, but also on external environmental requirements, such as local environmental protection standards, water quality discharge standards, and so on.

Which steam boiler is better for textile enterprises? Fangkuai boiler technicians recommend "Euromonitor" series customized gas steam boilers.

The "Euromonitor" series of customized gas-fired steam boilers use gas fuel, and the biggest feature is that the steam is very fast. After the boiler is started, it only needs to wait for 3-5 minutes to output high-temperature and high-quality steam with a temperature above 194°C. The steam has a very high purity and almost no water. This can save a fuel input cost for textile enterprises using steam boilers. Many other types of steam boilers require fuel to burn continuously for an hour or more to output high-temperature steam, and the fuel cost in this short period of time is wasted. This value will be higher if the boiler is started frequently.

The "Euromonitor" series of customized gas-fired steam boilers can also achieve low nitrogen emissions, and emissions below 18mg can be used in any city in my country. Beijing, Shanghai, Zhengzhou, Xi'an and other cities have implemented the 30mg emission standard, and 18mg can be used in that city, so you can avoid the strict inspection of the environmental protection department.

The "Euromonitor" series of customized gas-fired steam boilers are still very small in size and have very low requirements on the boiler room. It can be used in basement, semi-underground and above ground.

"Euromonitor" series of customized gas-fired steam boilers can also customize specific tonnage according to the needs of users, which is very flexible.

Consultation

Consultation