Converting coal-fired boilers to gas-fired boilers

2022-05-12 13:41:26

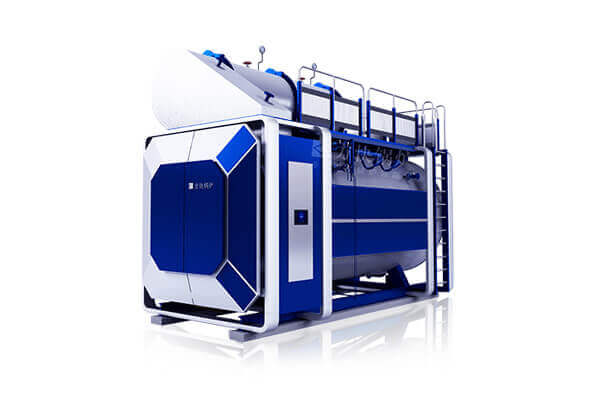

People pay more and more attention to the living environment, coupled with the adjustment of environmental protection policies by the Chinese government, coal-fired boilers with low thermal efficiency, serious pollution and high energy consumption are gradually eliminated, and cleaner, environmentally friendly, efficient and energy-saving gas-fired boilers are widely used. Of course, it is also a way to change the original coal-fired boiler to a gas-fired boiler, which can not only meet the emission requirements of our country, but also save the cost of purchasing a boiler.

How to change a coal-fired boiler to a gas-fired boiler? Fangkuai Boiler Company is an expert in this area.

First, the transformation principle of coal-fired boilers to gas-fired boilers

1. Maintain or improve the output and efficiency of the boiler, and the original rated parameters (steam temperature, pressure, feed water temperature, etc.) remain unchanged.

2. When changing the furnace, the pressure components should be moved as little or not as possible. Only the furnace chamber and combustion equipment can be changed. Wind resistance calculation, rational use of the original air supply and induction system.

3. Select the appropriate burner form and reasonable arrangement position according to the furnace structure to prevent the flame from directly scouring the water wall of the furnace or affecting the heat exchange, causing the temperature of the flue gas at the furnace outlet to be too high.

2. The main points of transformation from coal-fired boilers to gas-fired boilers

1. Boiler body

Coal-fired boilers usually use layer combustion, while gas-fired boilers use chamber combustion. Due to different combustion methods, there are great differences in the structure of the furnace. Usually, the furnace volume of coal-fired boilers is relatively large, so the furnace size is not suitable for simple replacement of gas burners, and needs to be carefully arranged.

2. Boiler auxiliary machine

Regardless of whether it is coal-fired or gas-fired, the ratio of the theoretical air volume required by the boiler combustion chamber to the calorific value of the fuel is approximately the same. Due to the large air leakage of coal-fired boilers, the excess air coefficient is much different from that of gas-fired boilers. The excess air coefficient at the furnace outlet of the layer-fired furnace is 1.4 to 1.6, so the actual flue gas volume and air volume are quite different. Generally, coal is 15% more than that of gas. ~60%. If the output remains unchanged after the gas is changed, the flue gas flow rate will be significantly reduced, the utilization rate of each heating surface will be greatly reduced, and the boiler induced draft fan will also have a margin of 15% to 60%. Ability should be able to meet. Considering reducing the cost of renovation, the scope of increasing the output of the boiler should be controlled within the maximum output of the original drum and induced draft fan.

The protection measures of gas boilers in terms of automatic control, chain protection and safety are much higher than those of coal-fired boilers. The operation is safe and stable, which greatly improves the working environment, reduces labor intensity, and helps to enhance the corporate image. With the support of policies, the price of gas is moderate, the gas source is stable, and the conversion of coal-fired boilers to gas has a wide application market, which is conducive to achieving a win-win situation of economic benefits and environmental protection standards.

How to change a coal-fired boiler to a gas-fired boiler? Fangkuai Boiler Company is an expert in this area.

First, the transformation principle of coal-fired boilers to gas-fired boilers

1. Maintain or improve the output and efficiency of the boiler, and the original rated parameters (steam temperature, pressure, feed water temperature, etc.) remain unchanged.

2. When changing the furnace, the pressure components should be moved as little or not as possible. Only the furnace chamber and combustion equipment can be changed. Wind resistance calculation, rational use of the original air supply and induction system.

3. Select the appropriate burner form and reasonable arrangement position according to the furnace structure to prevent the flame from directly scouring the water wall of the furnace or affecting the heat exchange, causing the temperature of the flue gas at the furnace outlet to be too high.

2. The main points of transformation from coal-fired boilers to gas-fired boilers

1. Boiler body

Coal-fired boilers usually use layer combustion, while gas-fired boilers use chamber combustion. Due to different combustion methods, there are great differences in the structure of the furnace. Usually, the furnace volume of coal-fired boilers is relatively large, so the furnace size is not suitable for simple replacement of gas burners, and needs to be carefully arranged.

2. Boiler auxiliary machine

Regardless of whether it is coal-fired or gas-fired, the ratio of the theoretical air volume required by the boiler combustion chamber to the calorific value of the fuel is approximately the same. Due to the large air leakage of coal-fired boilers, the excess air coefficient is much different from that of gas-fired boilers. The excess air coefficient at the furnace outlet of the layer-fired furnace is 1.4 to 1.6, so the actual flue gas volume and air volume are quite different. Generally, coal is 15% more than that of gas. ~60%. If the output remains unchanged after the gas is changed, the flue gas flow rate will be significantly reduced, the utilization rate of each heating surface will be greatly reduced, and the boiler induced draft fan will also have a margin of 15% to 60%. Ability should be able to meet. Considering reducing the cost of renovation, the scope of increasing the output of the boiler should be controlled within the maximum output of the original drum and induced draft fan.

The protection measures of gas boilers in terms of automatic control, chain protection and safety are much higher than those of coal-fired boilers. The operation is safe and stable, which greatly improves the working environment, reduces labor intensity, and helps to enhance the corporate image. With the support of policies, the price of gas is moderate, the gas source is stable, and the conversion of coal-fired boilers to gas has a wide application market, which is conducive to achieving a win-win situation of economic benefits and environmental protection standards.

Consultation

Consultation