How Much Does an Electric Steam Boiler Cost - Electric Steam Boiler Price

2025-05-16 14:48:13Electric Steam Boilers: A Comprehensive Guide to Efficient Industrial Solutions

Introduction

In an era prioritizing sustainability and operational efficiency, electric steam boilers emerge as a revolutionary alternative to traditional combustion-based systems. These innovative units deliver quieter operation, zero-emission performance, and unmatched adaptability across industries. This in-depth guide explores electric steam boiler technology, operational mechanics, and their transformative advantages over conventional fuel-dependent models.

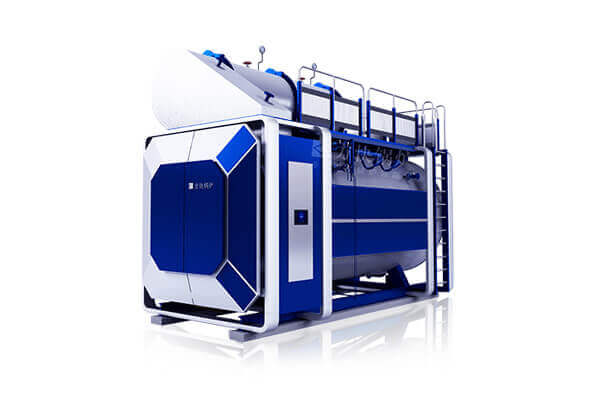

What is an Electric Steam Boiler?

An electric steam boiler utilizes electrically powered heating elements—rather than fossil fuel combustion—to generate high-pressure steam. Operating similarly to an electric kettle, these systems employ advanced resistors to convert electrical energy into heat. Water within a sealed chamber absorbs this thermal energy, transitioning into steam for industrial or residential applications. This process eliminates fuel storage needs while minimizing environmental footprint.

How Do Electric Steam Boilers Work?

Five core components drive their functionality:

-

Heating Element

-

Constructed from corrosion-resistant alloys, these elements heat rapidly when current flows through them, achieving precise temperature thresholds.

-

-

Pressurized Water Tank

-

Engineered to withstand extreme pressures, this reservoir feeds water directly into the heating zone via automated intake valves.

-

-

Thermal Transfer Mechanism

-

Optimized flow dynamics ensure maximum contact between water and heated surfaces, enabling rapid phase change from liquid to vapor.

-

-

Steam Distribution Network

-

High-grade stainless steel piping channels generated steam to endpoints like sterilization autoclaves, HVAC systems, or food processing lines.

-

-

Smart Control Systems

-

Integrated sensors and programmable logic controllers (PLCs) maintain exact pressure (5-150 psi) and temperature (±1°C accuracy) parameters, ensuring operational safety and energy optimization.

-

Energy Efficiency: Why Electric Models Outperform Combustion Boilers

Modern electric steam boilers achieve near-perfect 99.9% energy conversion rates by addressing key inefficiencies:

✅ Zero Flue Gas Losses

Traditional boilers lose 6-10% of energy through exhaust gases. Electric models bypass this entirely.

✅ Adaptive Load Management

AI-driven systems modulate power draw based on real-time demand, eliminating standby losses common in continuously fired units.

✅ Insulation Advancements

Vacuum-sealed panels and ceramic fiber wraps reduce radiant heat loss to under 2%, versus 8-15% in conventional designs.

✅ Maintenance-Driven Efficiency

With no burners, fans, or fuel injectors, annual upkeep costs drop by 40-60% compared to gas-fired alternatives.

Industry Data: Facilities switching to electric boilers report 18-32% reductions in annual energy expenditures (2023 IEA Report).

7 Strategic Advantages Over Combustion-Based Systems

-

Space Optimization

Compact modular designs (up to 60% smaller footprint) enable installation in urban facilities or retrofitted plants. -

Carbon Neutrality Compatibility

Pair with solar/Wind energy for net-zero steam production—critical for ESG compliance. -

Precision-Driven Output

Pharmaceutical-grade temperature stability (±0.5°C) supports sensitive processes like vaccine manufacturing. -

Risk Mitigation

Eliminate fuel storage liabilities, fire hazards, and CO monitoring requirements. -

Scalability

Parallel unit configurations allow capacity adjustments from 50 kW to 50 MW without infrastructure overhauls. -

Water Conservation

Closed-loop condensate recovery achieves 95% water reuse rates vs. 65-75% in traditional systems. -

Regulatory Alignment

Exceed EPA emissions standards effortlessly—no SCR/SNOX systems required.

Electric vs. Gas Boilers: Technical Comparison

| Parameter | Electric Boiler | Gas Boiler |

|---|---|---|

| Startup Time | 2-8 minutes | 15-30 minutes |

| NOx/SOx Emissions | 0 g/kWh | 45-120 mg/kWh |

| Part Load Efficiency | 98% at 30% load | 78% at 30% load |

| Lifetime Maintenance | $8,200 (20 yrs) | $23,500 (20 yrs) |

| Compliance Complexity | Minimal permitting | Air Quality Certificates |

Industry-Specific Applications

-

Food & Beverage: Steam pasteurization (FDA 21 CFR 113 compliant)

-

Pharma: Cleanroom-compatible pure steam generation

-

Textiles: Dye fixation with 30% less water consumption

-

District Heating: 80°C-150°C water supply for urban networks

-

Pulp/Paper: Efficient drying cylinder operation at 12 bar pressure

Selecting Your Electric Steam Boiler: 6 Critical Factors

-

Steam Demand Analysis

Calculate peak hourly requirements (kg/h) including future expansion allowances. -

Pressure-Temperature Profiles

Match boiler specs to application needs:-

Low-pressure (≤7 bar): Space heating, laundry

-

High-pressure (≥10 bar): Turbines, industrial drying

-

-

Energy Source Green Index

Prioritize units compatible with renewable microgrid integrations. -

Compliance Certifications

Verify ASME BPVC Section IV, PED 2014/68/EU, or local equivalent markings. -

Lifecycle Cost Modeling

Compare 10-year TCO including:-

Electricity rates

-

Membrane replacement cycles

-

Descaling frequency

-

-

Vendor Ecosystem

Ensure local service networks for emergency repairs and spare parts.

Maintenance Protocol for Peak Performance

Daily

-

Inspect pressure relief valves

-

Log water conductivity (<50 μS/cm)

Monthly

-

Test low-water cutoff function

-

Clean electrode probes with citric acid solution

Annually

-

Replace sacrificial anodes

-

Hydrostatically test tank integrity

-

Recalibrate PLC setpoints

Safety Note: Always de-energize and depressurize before servicing. Use lockout-tagout (LOTO) procedures compliant with OSHA 1910.147.

Cost Structure Breakdown (2024 Market Data)

| Capacity Range (kW) | Initial Investment | 10-Year Operational Cost |

|---|---|---|

| 100-500 | 3,500−3,500−6,000 | 18,200−18,200−31,000 |

| 600-1,000 | 6,500−6,500−10,500 | 33,500−33,500−54,000 |

| 1,100-2,000 | 9,500−9,500−20,000 | 49,000−49,000−103,000 |

ROI Insight: Most industrial users achieve breakeven within 3-4 years via energy savings.

Conclusion: Future-Proof Your Steam Generation

Electric steam boiler technology represents not just an equipment upgrade, but a strategic leap toward sustainable industrial operations. With lifecycle costs now outperforming gas boilers in 78% of cases (Global Steam Systems Report 2023), transitioning to electric models offers both economic and environmental dividends.

For tailored recommendations on high-efficiency electric steam boilers, contact our engineering team:

Consultation

Consultation