How to choose a gas boiler?

2021-12-31 14:47:49

Urbanization with increasing coverage not only brings more convenience to people’s lives, but also poses more challenges to boiler equipment that provides kinetic energy sources, such as tight space, requirements for the surrounding environment, higher requirements for automation and reliability, etc. Promote more use of gas boilers.

So, how to choose a suitable gas boiler ?

1. Boiler working pressure

The rated steam pressure of the boiler nameplate should be greater than the sum of the resistance of the steam supply pipeline and the working pressure required for production.

Please do not ignore the resistance of the steam pipe, because the higher the rated steam pressure, the higher the saturated steam temperature.

2. Boiler heating area

The heating area (heat transfer area) is an important (design) parameter of the boiler.

Because a boiler with a large heating area generally has a large output and a strong overload capacity; on the contrary, the output is small.

The boiler with the same capacity, relatively large heating area, lower exhaust gas temperature, higher boiler efficiency, and the heat generated by fuel combustion can be fully utilized and consume less.

3. Boiler blowdown

Blowdown is an effective measure to clean the inside of the boiler, remove sludge, and reduce scale.

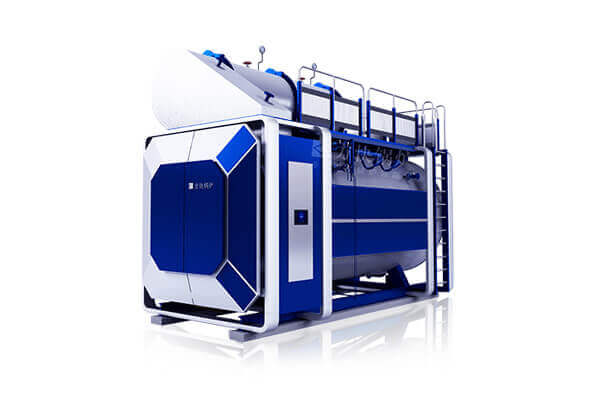

4. Furnace structure

The diameter of the bladder is also one of the important (design) parameters of the boiler.

After many boilers have been running for a period of time, carbon deposits in the furnace bladder, soot and soot deposits in the flue pipes, and even black smoke begins to waste fuel. The main reason is that the diameter of the furnace bladder is too small, and the atomized oil particles are sprayed on the wall of the furnace to be carbonized at a high temperature before burning.

Therefore, when choosing a gas boiler, you should try to choose a furnace with a larger diameter.

Five, furnace body

The quality of the furnace body is the standard for judging the quality of the boiler, which is mainly determined by the two links of design and manufacturing.

It is mainly manifested in the structure of the boiler and the layout of the heating surface and the selection of the temperature of each part, especially the temperature control of the furnace bladder (or furnace) outlet and the structure of the furnace body.

So, how to choose a suitable gas boiler ?

1. Boiler working pressure

The rated steam pressure of the boiler nameplate should be greater than the sum of the resistance of the steam supply pipeline and the working pressure required for production.

Please do not ignore the resistance of the steam pipe, because the higher the rated steam pressure, the higher the saturated steam temperature.

2. Boiler heating area

The heating area (heat transfer area) is an important (design) parameter of the boiler.

Because a boiler with a large heating area generally has a large output and a strong overload capacity; on the contrary, the output is small.

The boiler with the same capacity, relatively large heating area, lower exhaust gas temperature, higher boiler efficiency, and the heat generated by fuel combustion can be fully utilized and consume less.

3. Boiler blowdown

Blowdown is an effective measure to clean the inside of the boiler, remove sludge, and reduce scale.

4. Furnace structure

The diameter of the bladder is also one of the important (design) parameters of the boiler.

After many boilers have been running for a period of time, carbon deposits in the furnace bladder, soot and soot deposits in the flue pipes, and even black smoke begins to waste fuel. The main reason is that the diameter of the furnace bladder is too small, and the atomized oil particles are sprayed on the wall of the furnace to be carbonized at a high temperature before burning.

Therefore, when choosing a gas boiler, you should try to choose a furnace with a larger diameter.

Five, furnace body

The quality of the furnace body is the standard for judging the quality of the boiler, which is mainly determined by the two links of design and manufacturing.

It is mainly manifested in the structure of the boiler and the layout of the heating surface and the selection of the temperature of each part, especially the temperature control of the furnace bladder (or furnace) outlet and the structure of the furnace body.

Consultation

Consultation